AN ORGANIZED WORKPLACE IS A SAFER WORKPLACE

AN ORGANIZED WORKPLACE IS A SAFER WORKPLACE

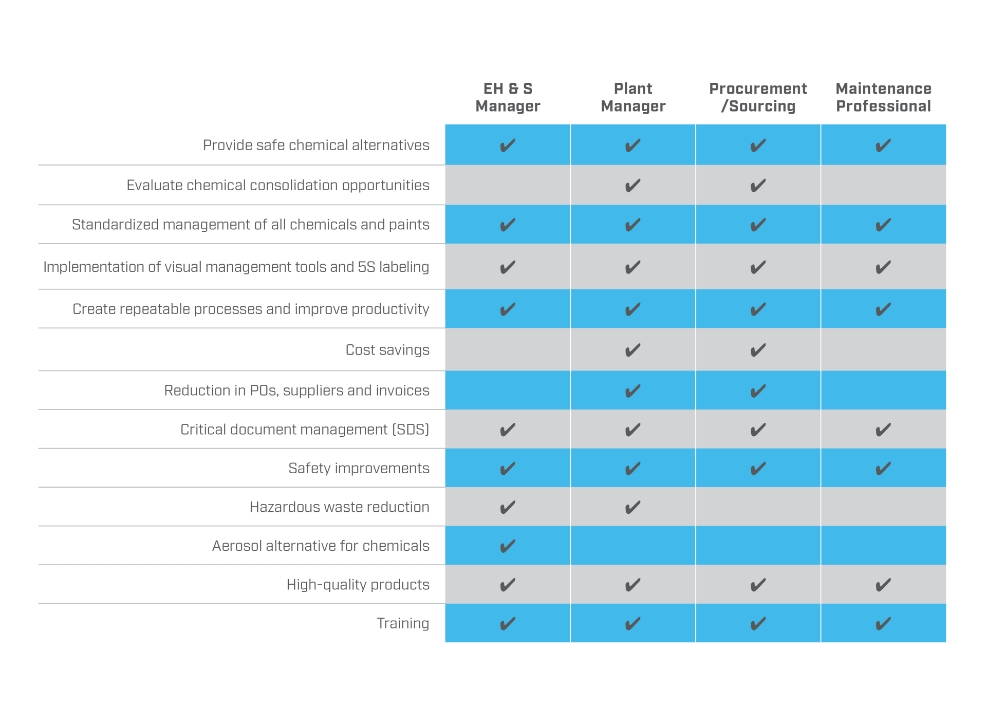

We believe every chemical housed in your facility matters. Backed by the Krylon® Continuous Improvement Program, our experts will help you create a storage system tailored to your specific needs, so you can keep your workplace running safely, smoothly and efficiently.

Why is chemical organization so important? Because improper storage or neglect can result in expensive audit fines, harmful usage, employee injuries, cost inefficiencies and inconsistent performance. That’s why our A.I.M. for Standardized Solutions Program and 5S methodology is key. Our team of National Field Specialists are here to help you reach your goals with our 3-step program.